VINATech has been committed to pursuing research in the area of carbon materials and development of nano-composite technologies. We have developed efficient solutions for fuel cells and deodorizing filter.

VINATech developed the original technology involving CNF (Carbon Nano Fiber) through independent research projects, in 2002. Subsequent development includes different carbon solutions including activating carbons, controlling the shape, composite and metal impregnated activation.

The application range of VINATech's carbon solutions includes CNF, catalyst support for fuel cells, MEA (Membrane Electrode Assembly), and electrode and filter materials.

In particular, we lead the world in production of catalyst support, catalyst for fuel cell and MEA.

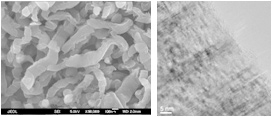

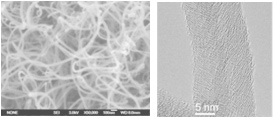

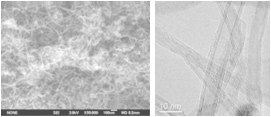

Carbon Nano Fiber(CNF) is a fiber-type carbon with a nano-sized(5 - 350 nm) and high crystallinity(d002 : 3.36 - 3.5Å) that is divided into Platelet type, Herringbone type, and Tubular type, according to the array shape of Graphene layers. Platelet type comes in where the graphene layers are arranged vertical to the direction of fibers and Herringbone type involves lamination with a specific inclination. Tubular type fiber is generated in parallel with the direction of other fibers.

VINATech develops Carbon Nano Fiber products with Herringbone type less than 10nm diameter, Platelet type with high crystalline properties(3.38Å or less), and VINATech can control the material properties.

You can scroll the content left and right.

| Type | Products | Fiber stems(nm) | Crystalline property (d002 : Å) |

Diameter of crystals (Lc002 : nm) |

|---|---|---|---|---|

| Platelet type | PCNF | 80~350 | 3.36 | 30 |

| Herring bone type | PCNF | 10~80 | 3.4~3.5 | 1~5 |

| Tubular type | TCNF | 5~50 | 3.4~3.5 | 2~5 |

You can scroll the content left and right.

| Type | Microscopic pictures | Forming structures | Surface Edges |

|---|---|---|---|

| PCNF |  |

|

Perpendicular to the fiber axis Diameter : 80~350 nm d002 : 3.36Å Lc002 : 30 nm |

| HCNF |  |

|

Symmetrically angled to the fiber axis Diameter : 10~80 nm d002 : 3.4~3.5Å Lc002 : 1~5 nm |

| TCNF |  |

|

Parallel to the fiber axis hollow Diameter : 5~50 nm d002 : 3.4~3.5Å Lc002 : 2~5 nm |

VINATech has a shape controlling technology that boosts the crystalline property through a physical process applied to the CNF surface and by high-temp thermal processing; the process changes the surface property by rearranging the edges. We also have a complex solution which improves the conductivity of electricity, radiation properties, dispensability, and specific surface area by combining the strengths of each component material.

VINATech's CNF is characterized by its excellent corrosion resistance developed through edge arrangement, dispensability secured by modification of surface properties, and great electricity conductivity and radiation effects ensured by complexation.

We have secured CNF fuel materials and can produce any CNF products with properties such as surface adhesion, distance between layers, and ion's interposing between layers optimized to the customer's application requirements.

You can scroll the content left and right.

| Patent No. | Patent Title | Year of application |

|---|---|---|

| IPC B82B-003/00 10-0483803-0000 | Fiber form nano carbon composition formula | 2002 |

| PCT/KR2003/002180 US7470418 B2 | Ultra-fine Fibrous Carbon And Preparation Method Thereof | 2003 |

| PCT/KR2005/004596 US20090004095 A1 | Porous Filamentous Nano Carbon And Method Of Forming The Same | 2005 |

| 10-1774706 | Manufacturing method of catalyst support and fuel cell catalyst including the same | 2017 |

| US 10,511,029 B2 | Method for Manufacturing Catalyst Support and Catalyst for Fuel Cell | 2019 |

VINATech is the only producer in the world of catalyst support and catalysts for fuel cells and MEA (Membrane Electrode Assembly).All of these products are based on the company's patented CNF materials technology

VINATech supplies catalysts and MEA having an excellent corrosion resisting property. These properties improve the life cycle of fuel cells by using crystalline carbons as a catalyst support.

We produce catalyst support divided into three types based on the corrosion resistance and shape, Two types of catalyst products classified by the catalyst support and two types of MEA products using our catalyst solutions which can be expanded to 300 cm2.

A fuel cell is a kind of generator that generates electricity by chemical reaction with hydrogen and oxygen as fuel.

Fuel cells generate fewer pollutants than fossil fuel production and are attracting attention as an eco-friendly energy source because most of them are water.

The fuel cell is used as a power source for transportation. (car, ship, train, drone, airplane, etc.)

It can be used as a boiler and distributed power generation at housing/commercial buildings, and for power plants.

You can scroll the content left and right.

| Type | Electrolytes | Operating temperatures(℃) | Application areas |

|---|---|---|---|

| PEMFC (Polymer Electrolyte Membrane Fuel Cell) | Polymer electrolyte | LT: < 80 HT: 120~180 |

Mobility Commercial building/house (1~200kW) |

| DMFC (Direct Methanol Fuel Cell) | Polymer electrolyte | < 80 | Portable, Commercial building (< 1kW) |

| AFC (Alkaline Fuel Cell) | KOH | < 100 | |

| PAFC (Phosphoric Acid Fuel Cell) | Phosphoric acid | < 220 | Commercial building (200kW) |

| MCFC (Molten Carbonate Fuel Cell) | Molten carbonate | < 650 | Commercial building, Power plant (100kW~MW) |

| SOFC (Solid Oxide Fuel Cell) | Solid oxide | 700 ~ 1,200 | Commercial building, Power plant (1kW~MW) |

VINATech's catalyst support, catalyst and MEA products are suitable for PEMFC and DMFC.

VINATech have developed and produced in-house Catalyst Support and Membrane Electrode Assembly having an excellent corrosion resisting characteristics. VINATech has improved the fuel cell’s life cycle by using crystalline carbon as a catalyst support.

Fuel cells require micro catalyst particles of 2nm to 3nm, to improve their catalytic performance. Small particles cannot be created only with catalysts. Catalysts must be distributed on catalyst support. VINATech’s fuel cell catalyst supports are Carbon Nanofiber or High crystalline carbon-black products which are designed to minimize the shortening of catalysts' life cycle due to corrosion.

You can scroll the content left and right.

| Product Name | *BET(m2/g) | *XRD(d002)(nm) | Fe content(ppm) | type |

|---|---|---|---|---|

| VFS-PL0100 | 60~70 | 0.336~0.380 | <200 | Platelet |

| VFS-HE0150 | 100~150 | 0.340~0.345 | <200 | Herringbone |

| VFS-SP0450 | 400~500 | 0.345~0.450 | <100 | Carbon black |

*1. BET: Specific surface area in accordance with the theories of Brunauer-Emmett-Teller

*2. XRD(d002): X-Ray Diffraction, inter-layer distance generated by diffraction of X-ray

VINATech's fuel cell catalyst support showed strong corrosion resistance in a carbon corrosion test based on electrochemical analysis. Corrosion resistance analyses per catalyst supports are as follows.

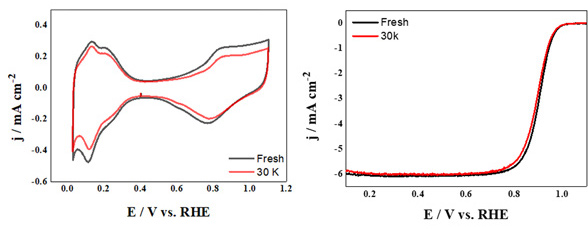

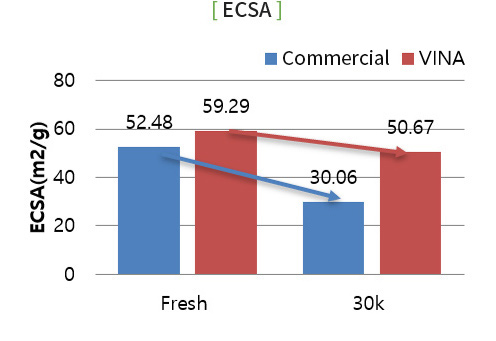

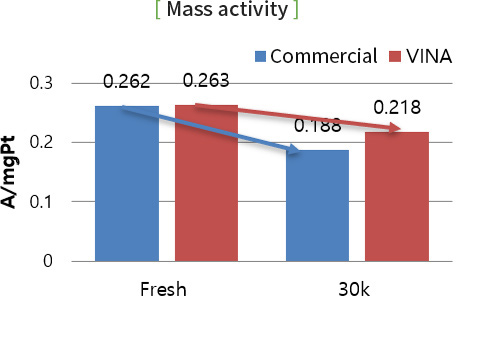

VINATech’s fuel cell catalysts are made of platinum, forming 2.5 to 3.0nm particles that are characterized by broad reaction areas and excellent corrosion resistance, which is suitable for applications that improve fuel cell’s performance and life cycle.

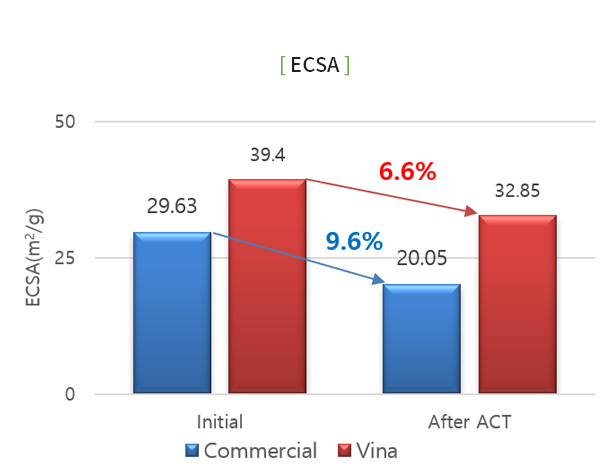

VINATech’s fuel cell catalyst products proved to be highly resistant to corrosion in a holding test satisfying carbon corrosion conditions. VINATech’s fuel cell catalyst also demonstrated a low decrement of reaction area.

You can scroll the content left and right.

| Division | Pt content (%) | ECSA(m2/g) | Particle size(nm) | Support type |

|---|---|---|---|---|

| VFC-HE | 20~60 | 30~45 | 2.5~2.8 | Herringbone |

| VFC-SP | 50~60 | 2.5~3.0 | Carbon black |

*ECSA : Electrochemical Surface Area

Highly Reliable Catalyst compared with commercial based on DOE Standard

Based on Design of Experiments, Half Cell Catalyst before and after deterioration test of 30,000 cycles

CV sweep profile : 0.6 V (3 s) ↔ 0.95 V (3 s)

30,000 Cycles

| Division | Commercial | VINA |

|---|---|---|

| Loss 30k | -42.71% | -14.54% |

| Division | Ref | VINA |

|---|---|---|

| Loss 30k | -28.18% | -17.10% |

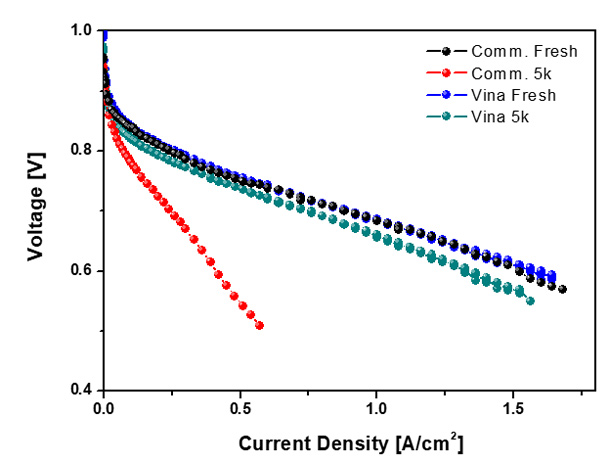

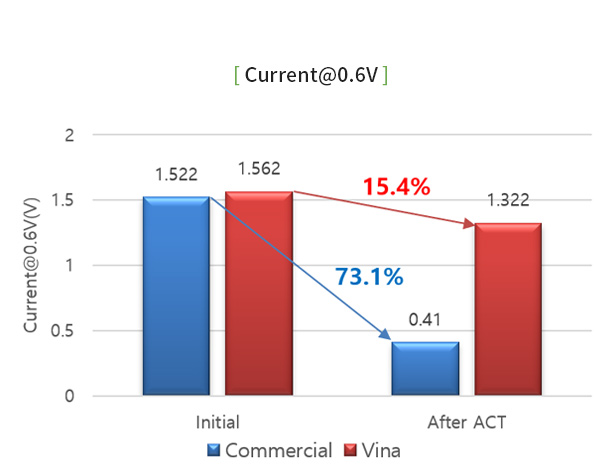

The characteristics of VINATech’s fuel cell Membrane Electrode Assembly proved to be excellent performance in discharging generated water, applied with our less-than 100nm electrode porosity controlling technology. VINATech MEA is suitable for improving the performance and life cycle of fuel cells.

Since 2002, VINATech started development for catalyst for fuel cell based on carbon technology and then expanded to Membrane Electrode Assembly products. VINATech Fuel Cell Product line-up is from Catalyst Support to Pt Catalyst and Membrane Electrode Assembly. VINATech’s R&D team developed VINATech’s own Membrane Electrode Assembly to be applied with Hydrogen fuel cell. Especially VFM-DM is developed for Direct Methanol Fuel Cell and VMF-PM can be applied with Polymer Electrolyte Membrane Fuel Cell.

You can scroll the content left and right.

| Product | Performance | Application | Size | Remark | |

|---|---|---|---|---|---|

| VFM | PM | 1.5A/cm2 @0.6V, 60℃ | Transportation, Stationary |

Customization Available |

CCM 5 layer, 7layer |

| DM | 200mA/cm2 @ 0.45V, 65℃ | Potable Back-up power |

CCG 5layer |

||

The only VINATech in the industry with in-house carbon support, catalyst and MEA technologies and manufacturing.

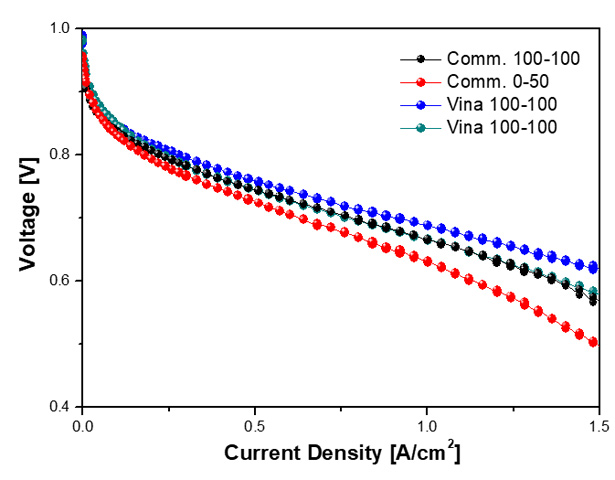

T Cell : 60°C

P Cell : An / Ca = 1 bara / 1bara

Flow : H2 / Air = ×1.5 / ×2.0

RH : An / Ca = 100% / 100%

0% / 50%

| Items | Before | mV @ 250 mA/㎠ | mV @ 1,000 mA/㎠ | mV @ 1,500 mA/㎠ | |||

|---|---|---|---|---|---|---|---|

| VINATech | 100-100 | 806 | 1.4 %↓ | 689 | 3.2 %↓ | 628 | 8.0 %↓ |

| 0-50 | 795 | 667 | 578 | ||||

| Commercial | 100-100 | 794 | 2.1%↓ | 667 | 5.3%↓ | 565 | 13.2%↓ |

| 0-50 | 778 | 632 | 496 | ||||

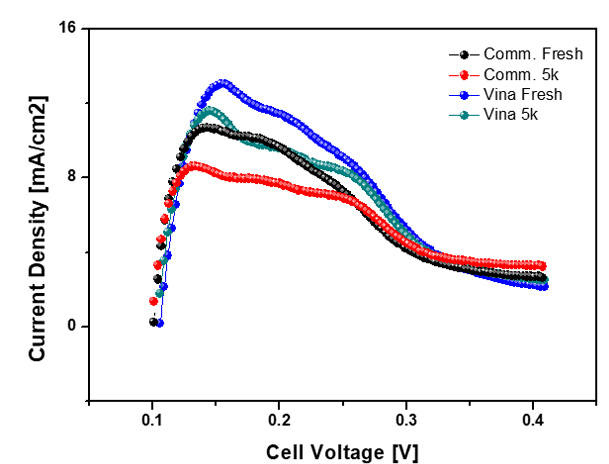

T Cell : 60°C

P Cell : An / Ca = 1 bar / 1 bar

Flow : H2 / N2 = 200cc / 600cc

RH : An / Ca = 100% / 100% Cycle : 500 mV/s (1.5 – 1.0V)

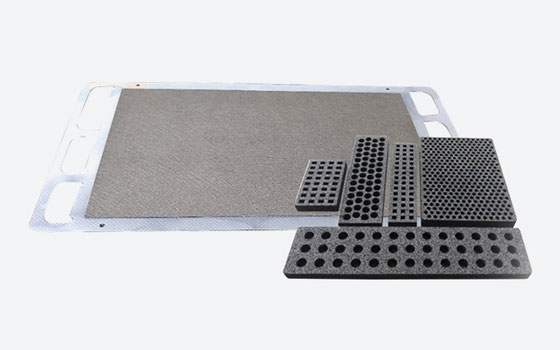

VINATech develops deodorizing filter based on their active carbon pre-treatment technology and supplies refrigerator deodorizing filter to a major white goods company.

VINATech offers their customised deodorizing filter which is equipped with VINATech’s activated carbon self absorption and metal catalyst impregnation technologies.

The deodorizing filter solution is using activated carbon and activated carbon fiber’s absorption function with pre-treatment technology which is specialized for the carbon absorption material, ensuring the VINATech deodorizing filter solution shows superior performance and long life span.

VINATech MEA products guarantee the very best performance along with the outstanding capability to combine with wide ranging applications even including low humidification environments.

| Item | pore | Diameter(nm) |

|---|---|---|

| BLACK | Macro-pore | > 50 |

| BLUE | Meso-pore | 2 - 50 |

| RED | Micro-pore | < 2 |

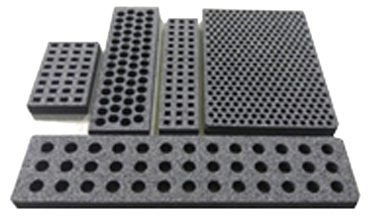

VINATech has developed a block-shape refrigerator deodorizing filter which uses activated carbon with high specific surface area. The filter is currently supplied to large Korean enterprises. The filter helps maintain fresh and clean air inside refrigeration units by eliminating major culprits of odor in refrigerators including Methyl Mercaptan, Hydrogen Sulphide, and Trimethylamine. We are also committed to developing filtering solutions to clean the cabin of cars as well as water purifiers and air cleaners, on the basis of our impregnating technology and by using metal catalysts optimized to each type of gas.

You can scroll the content left and right.

| Items | Specifications | Refrigerator deodorizing filters |

|---|---|---|

| Type | Carbon-block |  |

| Metal catalysts | Copper 3 wt% | |

| Binders | Polyethylene sphere binder 10 wt% | |

| Specific surface area | 600 m2/g or above | |

| Pore Volume | 0.28 cc/g or above | |

| Tap density | 0.5 g/cc or above | |

| Methyl Mercaptan destruction time | 1500 - 2000 min. | |

| Deodorizing efficiency | 90% | |

| Intensity of compress | 10 kgf/cm2 above |

VINATech's deodorizing filters use optimized metal catalyst impregnating technology specialized for gas elimination.

Our filters have proved excellent in their performance compared to other commercial filters of the kind.

| Item | pore | Diameter(nm) |

|---|---|---|

| BLACK | Macro-pore | > 50 |

| BLUE | Meso-pore | 2 - 50 |

| RED | Micro-pore | < 2 |