The carbon support is a key material for fuel cell catalyst, and the efficiency and durability of the fuel cell are greatly affected by the characteristics of the carbon support.

VINATech has own mass production technology by commercializing carbon support based on carbon control technology.

VINATech is promoting application and commercialization of other advanced technologies in addition to the currently secured carbon surface/shape control technology, activated carbon and carbon composite technology.

Through continuous development, we are developing carbon support that can further improve the efficiency and durability of fuel cells.

You can scroll the content left and right.

| Patent No. | Patent Title | Year of application |

|---|---|---|

| IPC B82B-003/00 10-0483803-0000 | Fiber form nano carbon composition formula | 2002 |

| PCT/KR2003/002180 US7470418 B2 | Ultra-fine Fibrous Carbon And Preparation Method Thereof | 2003 |

| PCT/KR2005/004596 US20090004095 A1 | Porous Filamentous Nano Carbon And Method Of Forming The Same | 2005 |

| 10-1774706 | Manufacturing method of catalyst support and fuel cell catalyst including the same | 2017 |

| US 10,511,029 B2 | Method for Manufacturing Catalyst Support and Catalyst for Fuel Cell | 2019 |

Carbon support has the following characteristics :

You can scroll the content left and right.

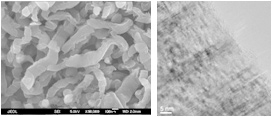

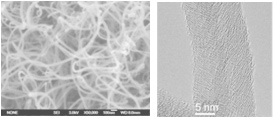

| Type | Microscopic pictures | Forming structures | Surface Edges |

|---|---|---|---|

| PCNF |  |

|

Perpendicular to the fiber axis Diameter : 80~350 nm d002 : 3.36Å Lc002 : 30 nm |

| HCNF |  |

|

Symmetrically angled to the fiber axis Diameter : 10~80 nm d002 : 3.4~3.5Å Lc002 : 1~5 nm |

You can scroll the content left and right.

| Division | *BET(m2/g) | *XRD(d002)(nm) | Type | Structure |

|---|---|---|---|---|

| VFS-P | 60~70 | 0.336~0.338 | CNF | Platelet |

| VFS-H | 100~150 | 0.340~0.345 | CNF | Herringbone |

| VFS-SP | 400~800 | 0.345~0.355 | Carbon black | Sphere |

*1. BET : The specific surface area in accordance with the theories of Brunauer-Emmett-Teller

*2. XRD(d002) : inter-layer distance generated by the diffraction of X-ray

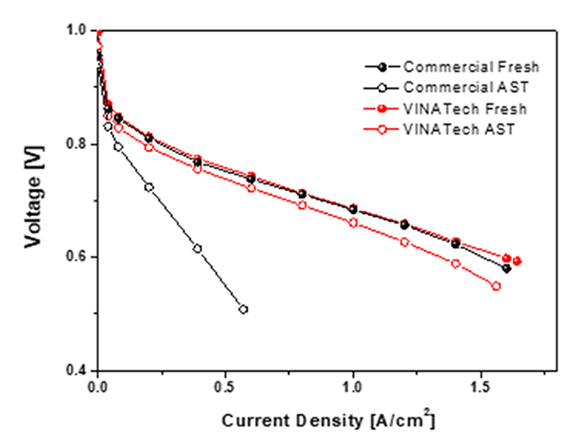

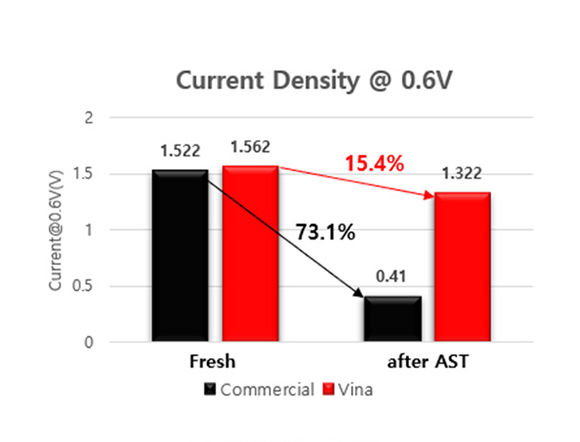

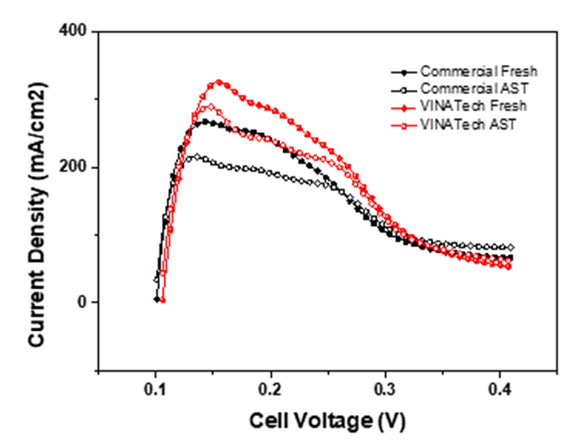

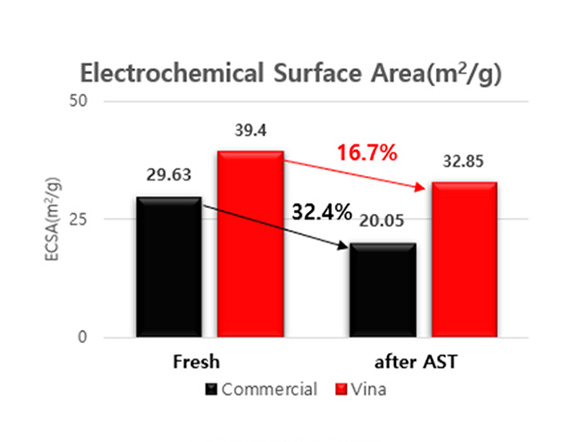

Electrochemical analysis (High voltage durability test) of MEA in Single cell (7-Layers, 25㎠)

T Cell : 60°C

P Cell : An / Ca = 1 bar / 1 bar

Flow : H2 / N2 = 200cc / 600cc

RH : An / Ca = 100% / 100%

Cycle : 500 mV/s (1.0-1.5V , 5k cycling)

Cycle : 500 mV/s (1.0-1.5V , 5k cycling)